Unveiling the Diverse Applications of Welding Services

Welding is an important process in the construction and manufacturing sector. Welding should be performed by professionals as it’s a crucial part of manufacturing. The application of heat and pressure is involved in welding. There are different types of welding services available which you can use in your project. It will lend strength to metal joints. When you hire a professional service provider, you will have a team that deals with welding projects by providing top-quality rolling services, no matter how complex the project is.

In this article we will talk about how welding services can be incorporated in your project.

The Wonderful World of Welding Techniques

There's not just one way to weld metal. Different techniques are used depending on the materials, thickness, and desired outcome.

Shielded Metal Arc Welding

Often called "stick welding," this useful technique can be put to different uses. Experts use an electrode coated in flux to create a protective shield around the weld area. It's a popular choice for applications like building construction and heavy equipment repair.

Gas Metal Arc Welding

Often called "stick welding," this useful technique can be put to different uses. Experts use an electrode coated in flux to create a protective shield around the weld area. It's a popular choice for applications like building construction and heavy equipment repair.

Flux-Cored Arc Welding

Similar to the gas metal arc welding, this method uses a continuously fed wire electrode but with a self-contained flux that eliminates the need for a separate shielding gas. This portability makes it well-suited for outdoor construction and field repairs.

Tungsten Inert Gas Welding

In this technique, experts use a non-consumable tungsten electrode and a separate shielding gas. It offers exceptional control and a clean weld pool, making it perfect for delicate applications like aerospace parts and thin metal fabrication.

Different Applications Of Welding Services

Construction

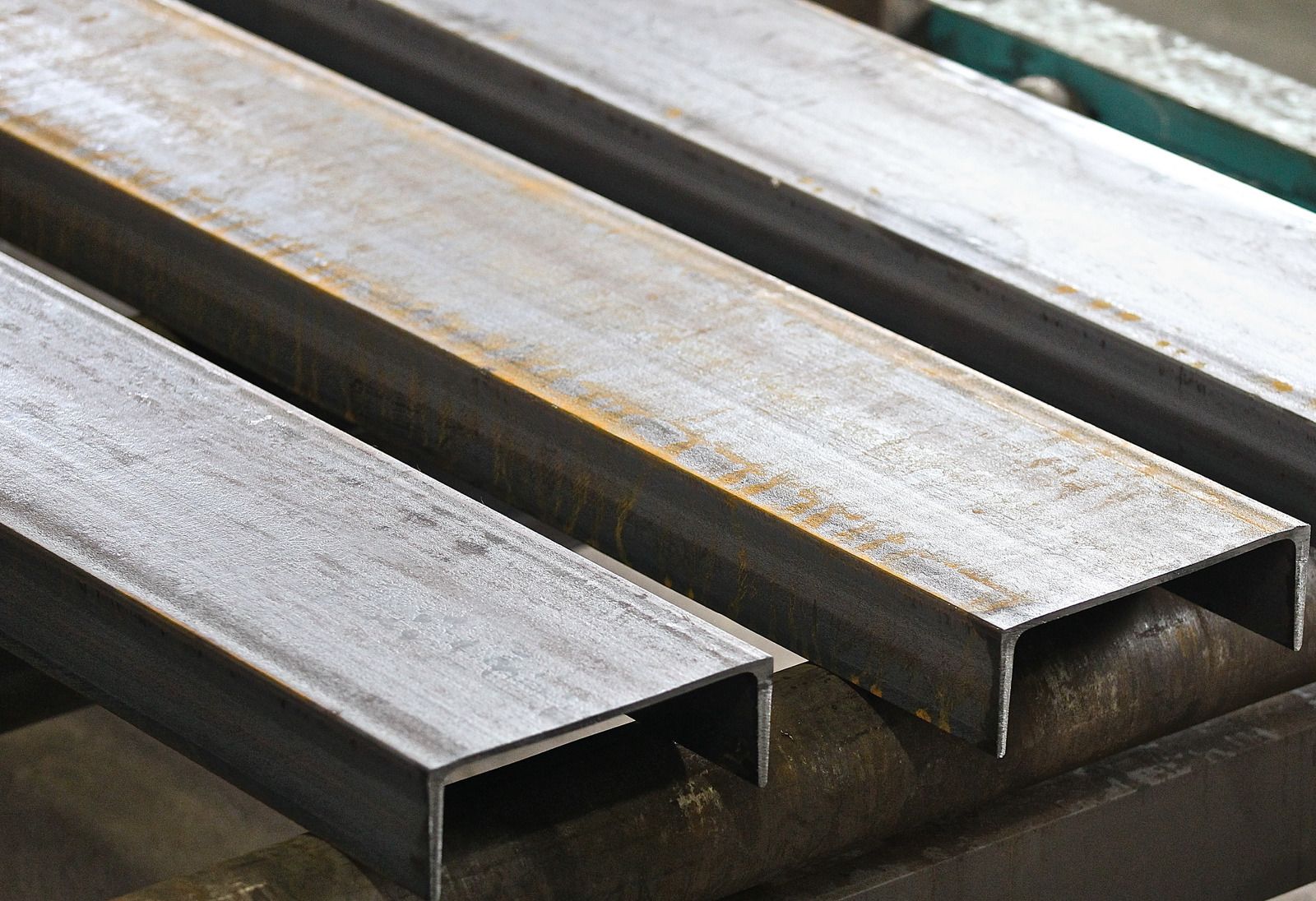

Welding is used in construction, especially in the steel beams that form the skeleton of any high structure. Welding is also used to join pipes and different parts in plumbing and central air frameworks.

Manufacturing

Welding comes in use while assembling many types of items, like vehicles, planes, boats, and apparatuses. Joining parts in modern hardware and equipment also requires welding of metals.

Repair and Maintenance

Welding services are crucial for maintaining and repairing countless structures and equipment. Broken pipes, damaged machinery, and even cracked car parts can often be given a new lease on life with skilled welding techniques.

Art and Sculpture

Welding can be used to creatively design any structure. Skilled metalworkers use welding to create stunning sculptures, intricate furniture pieces, and unique decorative elements.

Home Improvement

Even homeowners can benefit from welding services. From repairing gates and fences to installing custom railings or building backyard fire pits, welding can make your living spaces functional and useful.

Exploring The Diversity Of Welding

The next time you gaze at a skyscraper, drive your car, or admire a beautiful metal sculpture, take a moment to appreciate the invisible force behind it all – welding. This versatile and crucial process shapes our world, offering functionality, beauty, and lasting solutions for countless applications. So, the next time you have a metal project that needs attention, consider the wonders of welding and the expertise of professional welding services.