Angle Rolling Service

Angle Rolling Service in The Greater Cincinnati, Kentucky, Indiana, Illinois and Tennessee Area

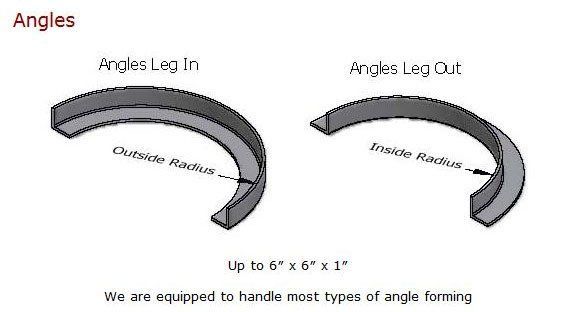

You can trust the dedicated professionals at Harvey Brothers Inc. for high-quality angle rolling services. Angles are rolled leg in / leg out for lintels, insulation spacers, and end caps for cylinders. We can roll up to 6" x 6 " x 1" leg out, 6" x 6" x 7/8" leg in & 3" x 3" x 1/4" heel in/out.

Trust Only A Reliable Angle Rolling Providers in Cincinnati, Ohio

When it comes to angle rolling services in Cincinnati, Ohio, reliability should be your priority. A reliable angle rolling provider will have the tools and expertise needed to bend metal into any shape or size you need. They also take safety seriously, so they use careful techniques and quality materials to ensure a perfect finish every time. With an experienced team of professionals backing up their work, you can trust that your job will be done with precision and accuracy. You'll get peace of mind knowing that your project is handled by someone reliable and trustworthy. Don't settle for anything less than the best - trust only a reliable angle rolling provider in Cincinnati, Ohio!

Our Angle Rolling Services

As a family-owned and operated business, we have provided Cincinnati, Ohio, residents with exceptional angle rolling services since 1921.

Angle Rings

Rolled Angle

Bent Angle

Rolled Stainless Angle

Aluminum Angle Rings

Rolled Aluminum Angle

Stainless Steel Angle Rings

What is The Significance of Angle Rolling in Steel Fabrication?

Angle rolling is a process of forming steel into different shapes. It is used to fabricate components for various industries, from automotive to aerospace and marine manufacturing. Angle rolling provides precise measurements with limited distortion, allowing for increased accuracy and repeatability in production. Additionally, angle rolling helps reduce setup times by eliminating the need to make multiple cuts or bends during component fabrication.

It significantly reduces labor costs and improves overall efficiency in steel fabrication processes. Furthermore, angle rolling eliminates stress points that could weaken material strength or cause failure when exposed to high temperatures or heavy loads over time. Therefore, it plays an essential role in ensuring optimal performance and durability of fabricated products without compromising safety standards.

What Are The Advantages of Angle Rolling?

Angle rolling is used to roll hot or cold metal into different shapes. This technique has many advantages over traditional methods of forming metal, such as welding and cutting. Angle rolling can produce complex parts with precise angles and curves, as well as greater strength than traditional methods offer.

With its cost-effectiveness and ability to create higher-quality products quickly, angle rolling offers an attractive alternative for those looking for an efficient way to form metal components. The process also reduces material waste and increases production speed since multiple pieces can be rolled at once in one pass. Additionally, angle rolling produces strong weld seams that are ideal for applications where superior strength is needed.

Why You Can Trust Harvey Brothers Inc.

For Angle Rolling Services in Cincinnati, Ohio?

Harvey Brothers Inc.

is a trusted provider of angle rolling services in Cincinnati, Ohio

We have provided quality metalworking and fabrication services to our customers for over 42 years. All of our operators are certified welders and use the latest technology to ensure accuracy throughout every process, from cutting to welding. At Harvey Brothers Inc., we value customer service above all else, which means we will go above and beyond to ensure you get exactly what you need at an affordable price while maintaining excellent quality standards.

FAQ's

What is angle rolling, and how is it used in fabrication?

Angle rolling is a metal forming process that bends structural angles into specific curves or shapes while maintaining the integrity of the material. This service is commonly used in industries such as construction, automotive, shipbuilding, and manufacturing for applications like staircases, railings, structural frames, and architectural designs. At Harvey Brothers Inc., we use advanced angle rolling machinery to achieve precise bends without compromising material strength, ensuring high-quality results for your projects.

What materials can be processed through angle rolling?

Harvey Brothers Inc. provides angle rolling services for a wide range of metals, including steel, stainless steel, aluminum, and other alloys. Each material has different bending properties, and our team ensures that the right methods are applied to maintain structural integrity while achieving the desired shape. Whether your project requires lightweight aluminum for architectural designs or heavy-duty steel for industrial applications, we have the equipment and expertise to handle it.

What industries benefit from angle rolling services?

Our angle rolling services cater to numerous industries, including construction, transportation, aerospace, energy, and manufacturing. Whether it's for curved steel beams in bridges, decorative elements in architecture, or precision-formed components for industrial machinery, our expertise helps companies achieve their fabrication goals efficiently. No matter the industry, Harvey Brothers Inc. ensures high-quality, precision-bent metal components that meet exact project requirements.

What are the tolerances and accuracy levels for your angle rolling services?

At Harvey Brothers Inc., we prioritize precision, ensuring that our angle rolling services meet the tight tolerances required for structural and aesthetic applications. Our advanced rolling equipment can maintain dimensional accuracy within industry standards, and our experienced operators carefully monitor each project to avoid deformities, warping, or unwanted distortions. If your project has specific tolerance requirements, we work closely with you to meet them.

What size and thickness of angles can you roll?

We can roll angles of various sizes and thicknesses depending on the material type and project specifications. Our equipment is capable of handling small, intricate bends for architectural applications as well as large, heavy-duty rolls for industrial structures. If you have specific size requirements, our team can assess your needs and provide customized solutions.

How does angle rolling differ from other metal bending methods?

Angle rolling is specifically designed to bend angles into curved or circular shapes without losing material strength. Other bending methods, such as press braking or plate rolling, may be better suited for different applications. Unlike traditional bending, which applies force at a single point, angle rolling gradually shapes the material over multiple passes, resulting in smoother and more precise curves.

Can angle rolling be used for custom fabrication projects?

Yes! Harvey Brothers Inc. specializes in custom metal fabrication, and our angle rolling services can be tailored to unique project needs. Whether you need custom railings, decorative metalwork, or structural components, our team collaborates with you to ensure the final product meets your specifications. Customization options include different radii, material choices, and finishing techniques to enhance aesthetics and durability.

How does angle rolling impact the structural integrity of the metal?

When performed correctly, angle rolling preserves the strength and integrity of the metal. At Harvey Brothers Inc., we use precise rolling techniques that minimize stress and deformation, ensuring that the final product retains its original load-bearing capacity. Our expertise ensures that each rolled angle meets safety and performance standards for structural applications.

What are common misconceptions about angle rolling?

One common misconception is that angle rolling weakens the metal or reduces its durability. In reality, when done professionally, it maintains structural integrity and can even enhance strength in some applications. Another misconception is that angle rolling is only for large-scale projects, but it is widely used for smaller, custom fabrications such as handrails, artistic metalwork, and precision components.

What challenges can arise during the angle rolling process?

Some challenges include maintaining uniformity in bends, preventing distortion, and achieving tight radii without compromising material integrity. At Harvey Brothers Inc., we overcome these challenges using state-of-the-art rolling equipment and skilled operators who carefully control each stage of the process. We also conduct thorough quality inspections to ensure all rolled angles meet project specifications.