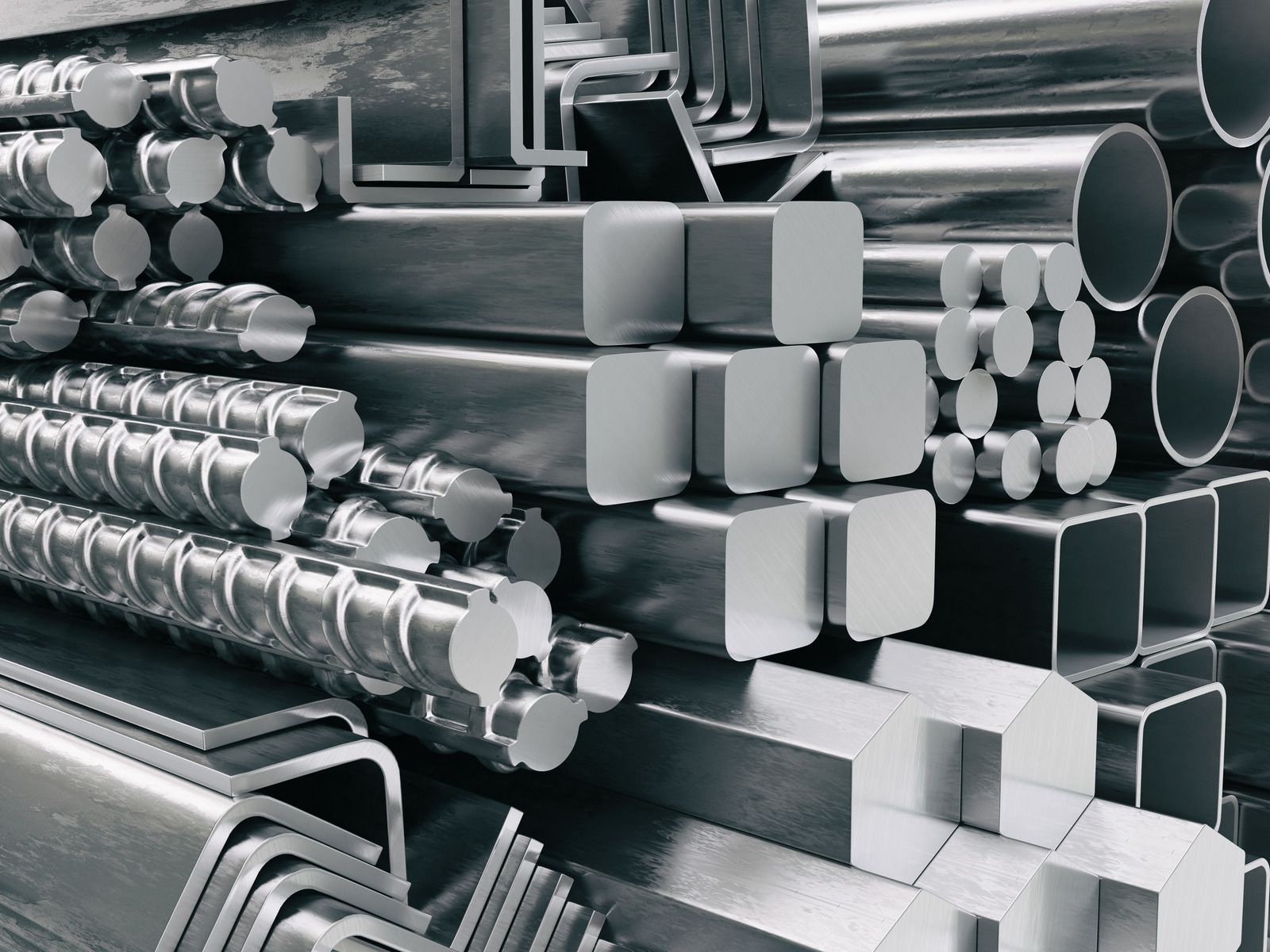

Ways Expert Pipe and Tube Rolling Prevents Structural Failures

The integrity of pipes and tubes is crucial in ensuring safety and efficiency in industries ranging from construction and manufacturing to aerospace and automotive. Expert pipe and tube rolling is a critical process that enhances the structural reliability of these components, preventing catastrophic failures. Below we explore ways how professional pipe and tube rolling contribute to structural integrity and prevent failures.

Shape precision and Consistency

The ability to obtain exact forms and consistency is one of the biggest benefits of skilled pipe and tube rolling. Inconsistencies in thickness in improperly rolled pipes and tubes can result in weak spots and eventual structural breakdowns. Manufacturers can guarantee that every pipe keeps a constant diameter and wall thickness by using sophisticated rolling procedures, which lowers stress concentrations that can jeopardize the structure.

Improved Material Strength and Durability

When done properly, rolling procedures improve the material's mechanical qualities. For instance, cold rolling strengthens the metal's tensile strength, increasing its resistance to deformation under stress. Additionally, good rolling eliminates internal faults and strengthens the grain structure of the metal, ensuring that it can bear enormous loads and adverse weather conditions without fracturing.

Failure Minimization

A structure's welded joints are frequently its weakest areas. Excessive welding is reduced when pipes and tubes are rolled to the necessary lengths and forms. This lessens the possibility of joint failures brought on by wear and tear, stress concentrations, or welding flaws. Seamless rolled pipes offer increased endurance and dependability in applications like high-pressure pipelines and bridges.

Enhanced Flexibility and Stress Distribution

Skilled rolling methods guarantee that pipes and tubes have the ideal curvature, which enhances their capacity to disperse stress uniformly. By doing this, localized stress spots that might cause fractures or cracks are avoided. For instance, correctly rolled tubes enhance the flexibility and robustness of structures in fields like aircraft engineering and shipbuilding, enabling them to sustain dynamic loads without failing.

Reduction of Internal Defects

Internal flaws like voids, inclusions, or abnormalities in poorly rolled pipes can gradually erode the structure. These flaws are removed by expert rolling techniques like precise calibration and controlled temperature rolling. This lowers the possibility of unexpected failures by guaranteeing that the finished product satisfies industry requirements for strength, durability, and dependability.

Customization

Professional rolling services provide customized alternatives for hydraulic systems, high-pressure gas lines, and structural supports that precisely match each application's needs. Manufacturers may guarantee that the pipes and tubes operate as best they can in their intended surroundings by customizing the rolling process to meet particular requirements, avoiding failures brought on by mismatched specifications.

Compliance with Safety Standards

Professional pipe and tube rolling companies adhere to stringent industry standards and regulations, ensuring that their products meet the highest safety criteria. Compliance with standards of ASTM, ASME, and ISO guarantees that the rolled pipes and tubes can withstand expected loads and operational conditions without failure.

Structural failures can have devastating consequences, leading to financial losses, safety hazards, and operational disruptions. Expert

pipe and tube rolling plays a vital role in preventing such failures by ensuring precision, enhancing material strength, reducing welding dependencies, and improving stress distribution. By investing in high-quality rolling processes, industries can ensure the longevity, reliability, and safety of their structures and systems.