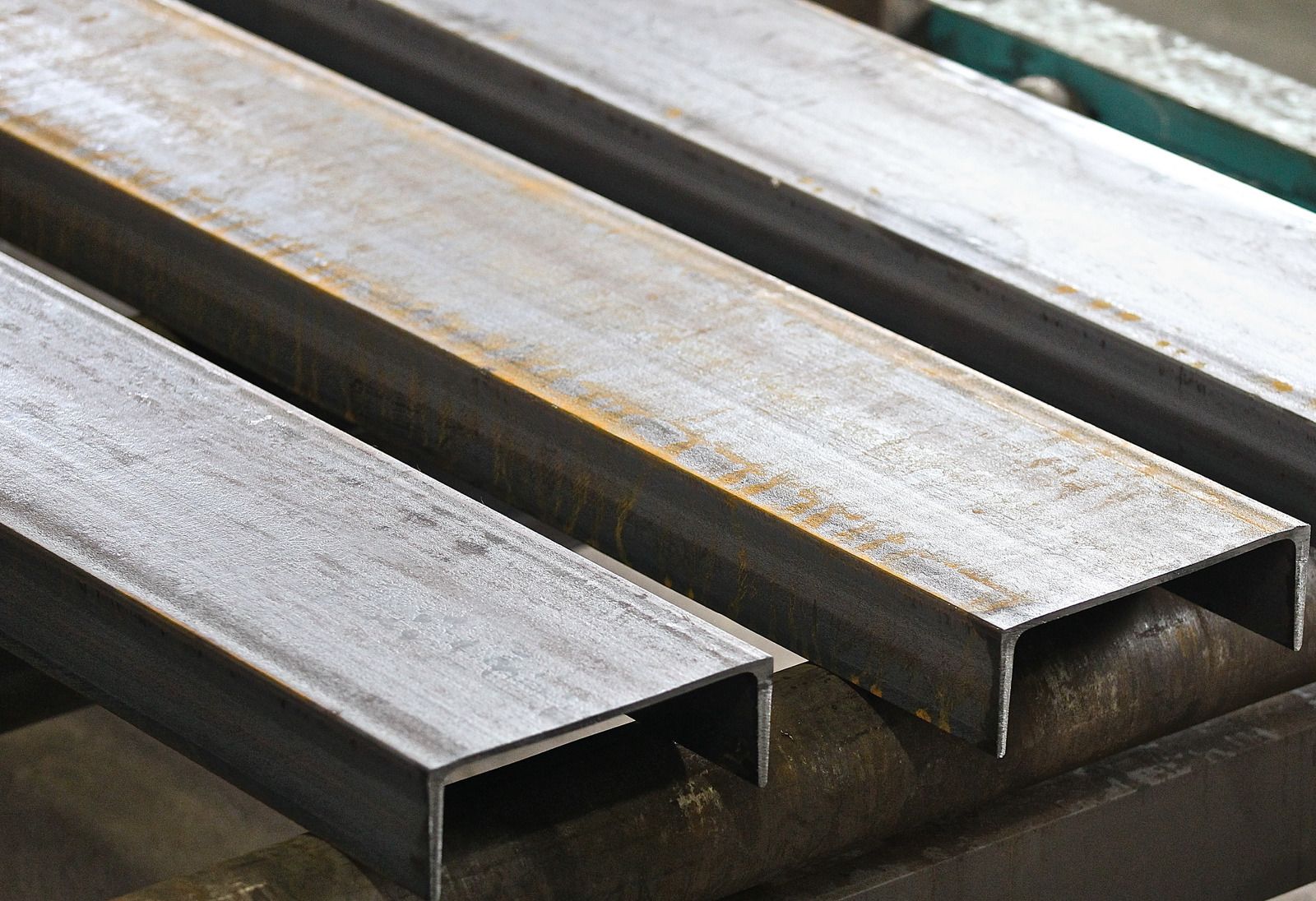

6 Advantages of Using Professionally Rolled Plate for Your Next Project

If you are currently in the process of selecting the proper material for your upcoming project, you should pay attention to the durability, strength, and reliability of the same. For many industrial applications and large-scale construction projects,

professionally rolled plate steel offers a sure-shot combination of these qualities.

Unmatched Strength and Durability

Rolled plates are well-used, based on their exceptional strength and ability to withstand significant loads and stresses. Manufactured from high-quality steel ingots, they undergo a rigorous rolling process that enhances their density and overall strength. If your project needs solid structural support like in bridges, buildings and heavy machinery, you need to go for rolled plates.

Precise Dimensions and Consistent Quality

Rolled plates need to have very precise dimensions and their quality should be uniform. Modern steel rolling mills utilize advanced technology to ensure rolled plates are produced keeping these parameters in mind. It means minimal material waste during fabrication and a seamless assembly process. If there are tight tolerances, the overall structural integrity of your project is maintained.

Wide Range of Sizes and Thicknesses

For customization options, rolled plates are the best options. You can get these from a reliable professional, in a vast array of sizes and thicknesses. This allows for a high degree of customization to meet the exact needs of your project. Whether you require thick plates for heavy equipment bases or thinner plates for cladding applications, rolled plate offers the perfect solution.

Excellent Versatility and Workability

If you want a material which is very versatile, rolled plate steel is what you should opt for. It can be readily shaped and various forms can be created from it. Techniques like welding, cutting, drilling, and bending can be applied to rolled plates to create a diverse range of components. This kind of versatile application makes it ideal for different ranges across various industries.

Cost-Effective Option in the Long Run

While the initial cost of professionally rolled plate might seem higher compared to some other materials, its durability and longevity translate to significant cost savings in the long run. Rolled plate structures require less frequent maintenance and repairs compared to structures built with less robust materials. Furthermore, the minimal waste during fabrication can also contribute to cost-effectiveness.

Sustainable Choice with High Recyclability

Steel is one of the most recyclable materials globally. Professionally rolled plates can be recycled numerous times without compromising its quality. This makes it an environmentally friendly choice for projects where sustainability is a major concern.

Hiring the Right Rolled Plate Steel Supplier

- Look for a reputable steel supplier with a proven track record in supplying high-quality rolled plate steel.

- Ensure the supplier offers a wide range of sizes, thicknesses, and grades of rolled plate aligned to what you need.

- Choose a supplier that adheres to strict quality control procedures and can provide certifications for the rolled plate steel they offer.

Professionally rolled plate steel offers a compelling choice for projects demanding exceptional strength, durability, and versatility. Getting to know its key advantages and choosing the right supplier, can help your project benefit from the long-lasting performance and reliability of rolled plate steel.