I-beam Rolling Service

I-beam Rolling Service in The Greater Cincinnati, Kentucky, Indiana, Illinois and Tennessee Area

I-Beams and bars are two of the most iconic forms of steel, and we can create custom sized ones for your next project with ease. Learn more about each type of rolling service below. We can bend I-Beams up to 15" flanges in / out for trusses, rails, and a variety of commercial projects.

Why You Need A Trusted I-Beam Rolling Service Provider in Cincinnati, Ohio?

A trusted I-beam rolling service provider in Cincinnati, Ohio, is essential for any business needing to roll large steel beams. Not only does the rolling process increase efficiency, but it also greatly reduces costs associated with traditional cutting and welding. A reliable provider will guarantee high-quality results every time and keep production on schedule.

Depending on your needs, they can handle orders of all sizes, both residential and commercial use. With their expert staff and advanced equipment, they can produce precision bends without compromising the structural integrity of each beam or pipe you need to be rolled.

Furthermore, having a reputable provider nearby means there is no need to ship materials long distances, which can incur additional costs or delays in delivery time due to transportation methods. As one of Ohio's largest cities with an abundant population base offering a wide range of services, it makes sense why someone would seek out a trusted I-beam rolling service provider in Cincinnati, Ohio, when looking for professional work done right the first time!

What Are The Best Uses of I-Beam Rolling in Steel Fabrication?

I-beam rolling is one of the best ways to fabricate steel. It can be used in various applications, including structural support, bridges, construction, and manufacturing. The process involves forming a beam by bending or rolling metal into an I-shaped profile that then adheres to predetermined dimensions and specifications. This allows for superior strength and stability in comparison with other methods of fabrication, such as welding or bolting. Additionally, I-beam rolling allows producers to create structurally sound designs at reduced costs due to its increased accuracy and precision compared to traditional fabrication techniques. With these advantages, it's no wonder why I-beam rolling is one of the most popular choices for steel fabrication today!

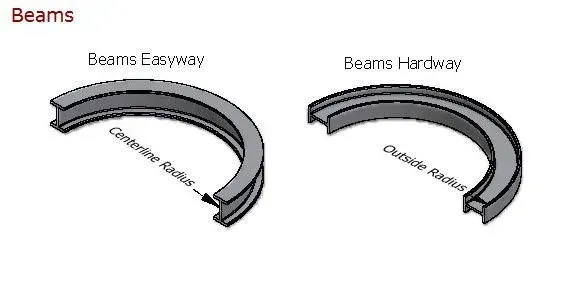

What Are Different Types of Beams in I-Beam Rolling?

I-beam rolling shapes metal into various structural shapes, such as beams or columns. Some common types of I-beam rolling include: rolled steel beams, aluminum beams, stainless steel beams, cast iron beam, and H sectioned beam. The I-beams are formed using a special type of rolling mill machine, and they come in different sizes and weights depending on the application.

- Rolled steel beams are typically used for applications with high strength but low weight requirements.

- Aluminum beams can be applied in areas where corrosion resistance is needed.

- Stainless steel and cast iron beams offer greater durability than other materials due to their higher tensile strength.

- H-sectioned beam offers an aesthetic style that adds beauty to any structure built with them.

Harvey Brothers Inc.

- Your Trusted Partner For I-Beam Rolling Services in Cincinnati, Ohio

Harvey Brothers Inc. is your trusted partner for I-beam rolling services in Cincinnati, Ohio. With over 42 years of experience in the industry, we have established ourselves as a reliable and reputable provider with an experienced team of experts who use the latest technology to deliver quality results that exceed your expectations. We offer a wide range of services, including beam straightening, bending, and punching, to meet your custom I-beam needs.

From small projects to large ones, you can count on us for all types of steel fabrication needs. Whether it's rolling or forming sheet metal parts or creating curved shapes from flat stock materials, our experienced staff will work closely with you to ensure that you get exactly what you need when you need it. Contact us today and discuss how Harvey Brothers Inc. can help make your project happen!

FAQ's

What is I-beam rolling, and when is it necessary?

I-beam rolling is the process of bending structural steel I-beams into curved shapes for applications such as arches, circular structures, or architectural designs. It’s used when straight beams don’t suit the design or structural needs—such as curved roofs, tunnels, stadiums, or bridges. Rolling must be precise to avoid deforming the flanges or web of the beam. Harvey Brothers Inc. uses specialized machinery to maintain structural integrity throughout the rolling process.

What types and sizes of I-beams can Harvey Brothers roll?

We work with a wide range of sizes and materials, including both wide flange (W-beams) and standard I-beams. Our facility accommodates everything from small architectural elements to large-scale industrial beams. Each beam is assessed for its rolling radius, grade, and potential stress points before processing. We encourage customers to provide specifications early so we can confirm feasibility and ensure the right equipment is allocated.

How do you ensure structural integrity during and after the rolling process?

Maintaining the strength of the beam is critical. We control the rolling speed, temperature, and pressure to minimize stress on the material. For tight radii or high-strength beams, we often use incremental rolling or heat-assisted methods. Post-rolling inspections check for distortion, cracking, or warping. Our precision approach helps ensure that your beam not only fits your design but meets load-bearing requirements.

Is it better to roll beams before or after fabrication (cutting, welding, etc.)?

Rolling should typically be done before welding or cutting to prevent uneven deformation or weakening of weld seams. Post-fabrication rolling risks damaging the finish or affecting the alignment of bolt holes and connections. At Harvey Brothers, we often collaborate with fabricators early to determine the ideal workflow, ensuring a smooth transition between rolling and final fabrication stages.

Can curved beams support as much weight as straight beams?

Yes, when properly rolled and engineered, curved I-beams can support significant structural loads. However, the distribution of forces is different, so engineering calculations must consider the curve's geometry. We work with your structural engineer to ensure the rolled beam's specifications meet load and safety standards. The misconception that curved beams are inherently weaker often stems from poor rolling practices, which we avoid through precision and experience.

What’s the minimum radius you can roll an I-beam to?

Minimum radius depends on beam size, profile, and material grade. Smaller beams can typically achieve tighter radii, while larger beams require wider curves to avoid flange deformation. We offer guidance on minimum bend radii based on industry standards and real-world performance. Trying to roll beyond those limits risks damaging the beam and compromising safety—so we always prioritize integrity over aggressive bends.

Do you offer custom rolling for architectural designs?

Absolutely. We work closely with architects and contractors on custom projects for arches, spirals, domes, and decorative steel features. These projects often require tight tolerances and a collaborative approach. We can create mock-ups, provide shop drawings, and even suggest design adjustments to ensure form and function are balanced. Our team thrives on turning complex ideas into functional steel structures.

How does I-beam rolling differ from angle, tube, or channel bending?

Each material has a unique cross-section and structural behavior. I-beams require more specialized handling due to their flanges and web. Improper rolling can lead to flange buckling or web distortion. Channel and angle rolling typically involve simpler profiles but may require mandrels to maintain shape. Tube rolling demands internal support to avoid collapse. Harvey Brothers has expertise across all these materials but applies different techniques for each.

What industries typically require I-beam rolling services?

We serve a wide range of industries including commercial construction, transportation, industrial facilities, sports venues, and energy infrastructure. For example, curved beams are used in stadium roofs, railway tunnels, tank support structures, and even amusement parks. Whether it’s aesthetic or structural, rolled beams provide versatility and strength in ways straight beams cannot.

What documentation do you provide with the completed beams?

We provide certificates of compliance, rolling logs, and dimensional verification upon request. For large or structural-critical projects, we also offer inspection reports and test results. This documentation helps you meet project specs, satisfy engineers, and pass local building inspections. Our transparent documentation process gives contractors peace of mind that quality standards were met.