6 Reasons Quality Plate Rolling Saves You Money

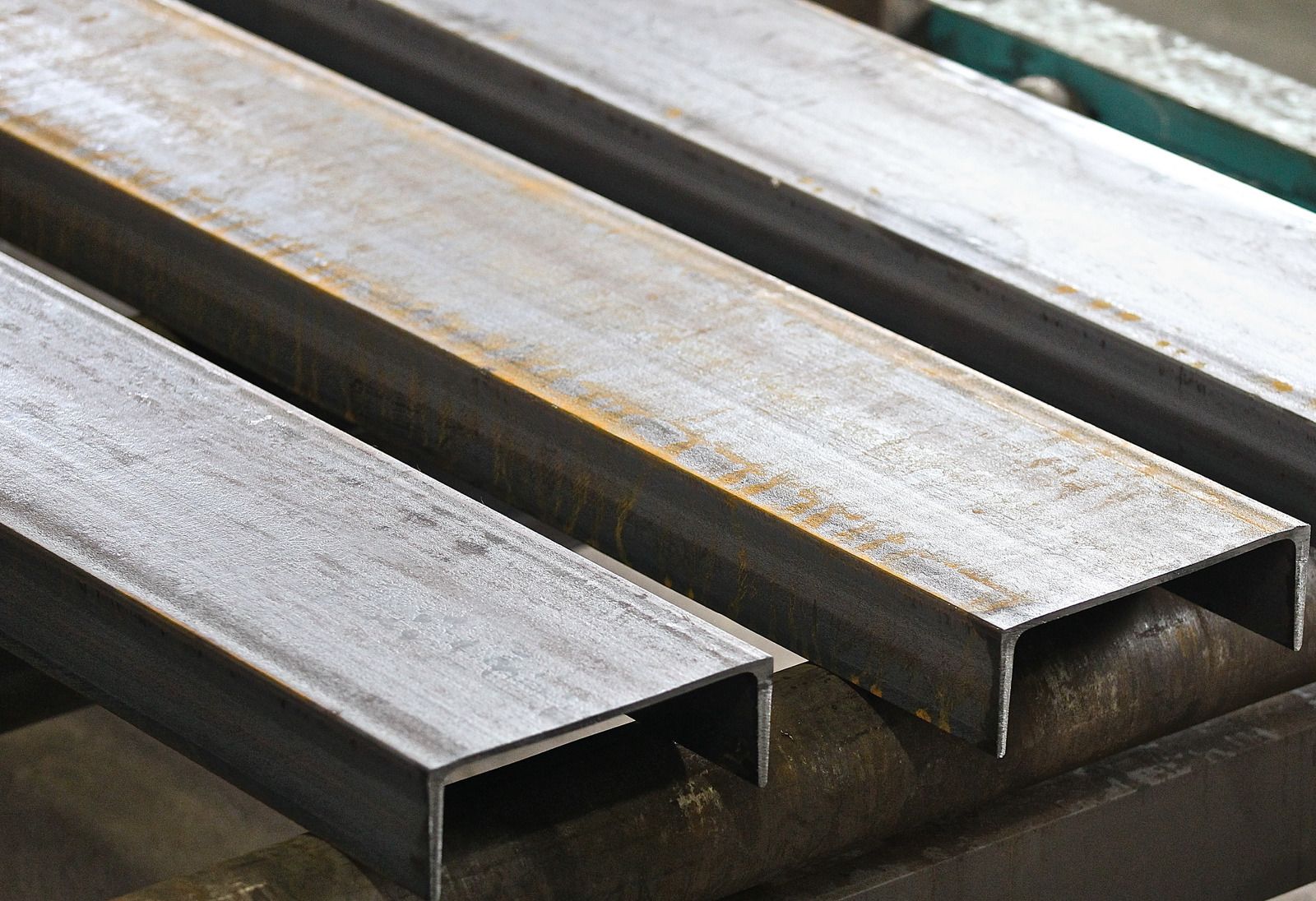

Plate rolling shapes metal sheets for various industries. Construction, manufacturing, and automotive sectors rely on precise metal forming. Poor rolling increases costs through wasted materials, extra labor, and frequent repairs. High-quality processes prevent these issues, providing accurate and durable results.

Properly rolled metal maintains strength, preventing failures. Defective shapes lead to cracks, weak spots, and additional corrections. Errors slow down production, increasing expenses. Investing in reliable rolling techniques improves efficiency, reducing delays and minimizing waste.

Durability, efficiency, and safety depend on precision.

Quality plate rolling delivers long-term cost savings while improving overall project success. The following points explain how businesses reduce expenses through better metal rolling.

1. Reduces Material Waste

Incorrect rolling produces defects, leading to discarded materials. Mistakes create uneven surfaces, requiring extra cutting or reshaping. High-quality methods reduce these problems, lowering raw material expenses.

Less waste means fewer purchases, cutting unnecessary spending. Scrap metal from poor rolling increases costs, adding strain to budgets. Precise shaping eliminates errors, allowing projects to use materials efficiently.

2. Lowers Repair and Replacement Costs

Weakly formed metal fails under stress, requiring frequent repairs. Cracks, bends, and distortions develop when rolling lacks accuracy. Strong, well-rolled components last longer, reducing expenses.

Replacing damaged parts delays projects, increasing labor costs. Proper rolling techniques create durable structures, preventing expensive replacements. Fewer breakdowns mean businesses avoid interruptions and additional spending.

3. Saves Time in Production

Accurately rolled plates fit seamlessly into assemblies, reducing adjustments. Workers spend less time fixing defects, improving overall productivity. Misaligned sections slow down welding and construction, causing delays.

Faster production lowers labor costs. Completing tasks without corrections increases efficiency, allowing businesses to meet deadlines without extra expenses. Smooth operations lead to faster project completion.

4. Reduces Energy Consumption

Flawed rolling requires additional shaping, consuming more power. Excess welding, bending, and cutting raise energy costs. Precision eliminates unnecessary processing, lowering electricity use.

Machinery operates efficiently with proper rolling techniques. Reworking metal strains equipment, increasing maintenance needs. Precise rolling methods improve production efficiency, reducing energy-related expenses.

5. Improves Safety and Reduces Liability

Defective metal parts create hazards, increasing workplace risks. Cracks or misaligned sections cause failures, leading to accidents. Stronger materials improve safety, protecting workers and equipment.

Accidents result in liability claims, legal fees, and project setbacks. Businesses avoid financial losses by using properly rolled metal. Fewer defects mean safer structures, reducing the risk of costly incidents.

6. Enhances Product Quality and Customer Satisfaction

Well-rolled metal improves product performance. Smooth, accurate surfaces create reliable components. Clients receive better materials, increasing confidence in the final product.

Customer complaints decrease when parts meet expectations. Poor quality leads to refunds, warranty claims, and lost business. Consistently well-formed metal strengthens long-term relationships, boosting revenue.

Quality plate rolling prevents waste, reduces repairs, and speeds up production. Lower energy use, better safety, and improved product reliability lead to long-term savings. Investing in precision metal forming helps businesses cut costs while delivering stronger, more efficient results.