Why Material Selection in Channel Rolling is Important

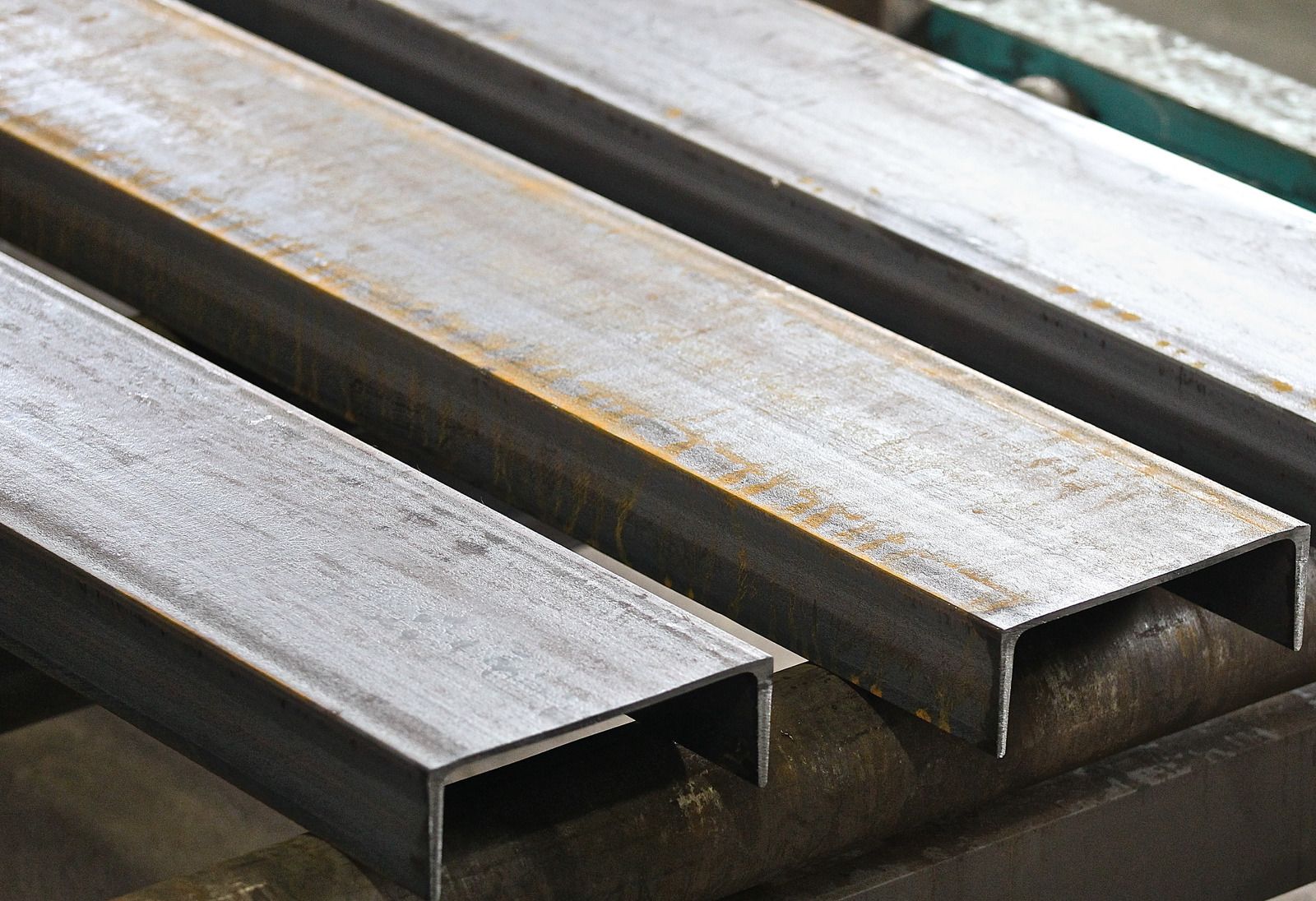

The foundation of engineering and production processes and material selection significantly impacts a product's result. This is best demonstrated by

channel rolling, a flexible method for forming metal or alloy into exact channels with precise features. The choice of material in channel rolling determines the product's longevity. The performance is also determined by its visual appeal, from the detailed workings of everyday devices to the massive structures that define our metropolitan landscapes. Let's look at the significance of material selection in channel rolling and how it affects many aspects of our lives.

Significance Of Material Selection In Channel Rolling

Strength and Durability Of The Product

The material choice primarily determines the final product's strength and durability. Every material, be it aluminum, steel, or another metal alloy, has certain qualities that determine its strength. Manufacturers can shape these materials into customized shapes using channel rolling precisely, maximizing their strength and weight ratio for unmatched performance and endurance.

Finished Product's Weight and Efficiency

Material selection dramatically influences the finished product's weight and efficiency, especially in the aerospace and automotive sectors, where every bit counts. All solid and lightweight materials, such as carbon fiber composites or titanium, can significantly improve performance and fuel efficiency. Manufacturers can create streamlined profiles that save weight without sacrificing the structure's integrity by utilizing channel rolling processes.

Cost-Effectiveness

Manufacturers can balance the original expenditure and total cost of ownership by considering factors like lifetime, energy efficiency, and maintenance requirements. Throughout the product lifecycle, investing in long-lasting materials that require less maintenance and exceptional longevity can result in significant cost savings and increased returns on investment.

Customization and Design Flexibility

Due to the wide range of materials available, designers have an unmatched amount of freedom when creating custom channel profiles for particular uses. Channel rolling promotes experimentation by allowing designers to investigate different materials and shapes, supporting product design, and using innovation.

Environmental Impact

Choosing a suitable material for channel rolling becomes even more critical when environmental concerns are growing. Recyclable material selection and environmentally friendly production techniques can reduce the release of carbon and waste generation. This may lead to an eco-friendly environment.

Aesthetic Appeal

Beyond practicality, material selection significantly impacts the final product's visual appeal. Material aesthetics impact our constructed environment and cultural landscape, whether it's the natural appeal of used copper or the clean shine of stainless steel. Channel rolling preserves the structural integrity and functional performance of items and structures by enabling producers to obtain precise geometries and finishing touches while improving their appearance.

In summary, regarding channel rolling, material choice goes beyond simple mechanics and represents an objective that includes environmental sustainability, cost-effectiveness, performance, and design aspects. Provided with an in-depth knowledge of material features, producers can make well-informed decisions that maximize the product's lifespan, improve functions, and accelerate efficiency while minimizing their adverse effects on the environment. The need for careful material selection in channel rolling will only increase as materials science develops further, influencing the span of future generations. People can also take the help of trained experts who can assist in choosing materials.