Types of Angle Rolling Machines: From Manual to Automated

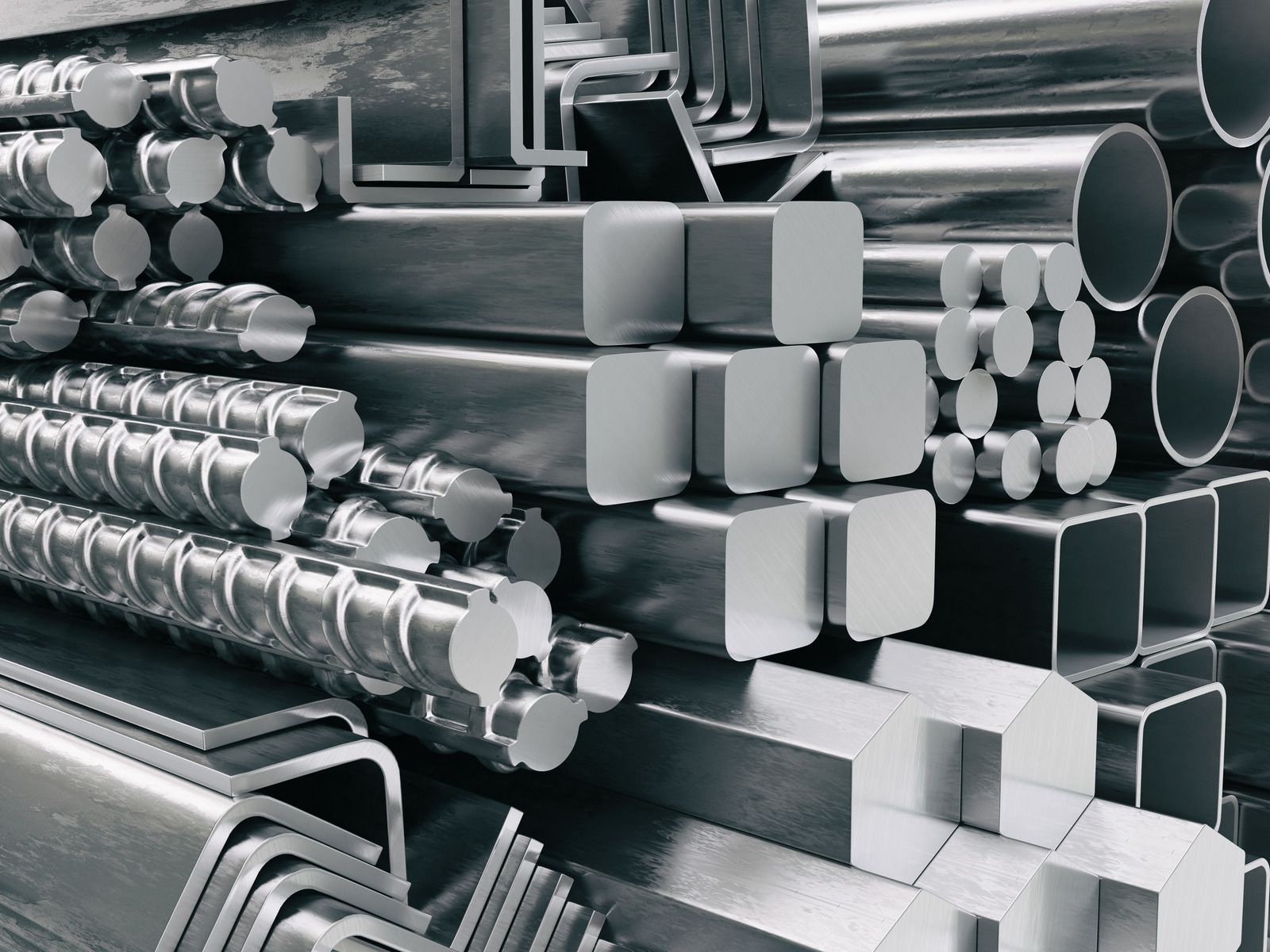

Angle rolling machines can shape a flat sheet of metal into angle irons, solid squared, pipes, round tubing, or a lot of other shapes. These machines are of great importance in different industries like construction and even for metalworking. The machines have to be of high quality so that they can be bent without compromising the structural strength of the building they are used for. The machines should be able to cater to the decorative purposes as well. Many kinds of angle rolling machines are available, each with its own capabilities and applications.

Manual Angle Rolling Machines

The most common kind of machines are the ones that need manual labor. Manual angle rolling machines, as their names suggest, need human operators to physically manipulate the machine to bend the metal. These machines typically consist of a frame with rollers or a bending wheel. The person operating the machine needs to be an expert to know when to manually feed the metal angle into the machine and how much force to apply so that it can be bent. They are best suited for small-scale operations or occasional bending tasks as they might not be very efficient.

Hydraulic Angle Rolling Machines

Hydraulic cylinders power hydraulic angle rolling machines. There is a lot of force needed to bend the metal. These machines offer greater precision and speed compared to manual machines. You can expect hydraulic machines to be able to handle larger and thicker metal angles. They are commonly used in metalworking shops and construction sites.

Electric Angle Rolling Machines

Electric angle rolling machines are powered by electric motors, which drive the bending mechanism. They offer similar precision and speed to hydraulic machines but are often more energy-efficient. Electric machines are a good choice for applications where hydraulic power is not readily available or desired.

Automated Angle Rolling Machines

Automated angle rolling machines have computer controls and automation systems. It enables the machine to allow precise and efficient bending operations. These machines can be programmed to perform complex bending sequences, reducing the need for manual intervention. Experts use them for large-scale manufacturing. They can lead to a high volume of production. The quality is paramount, and you can use it for repeat jobs where the same kind of rolling is required multiple times.

Choosing the Right Angle Rolling Machine

Ideally, a professional company will decide whether your project requires manual rolling or automated hydraulic ones. It is good to know what criteria are considered before a machine is used. Thicker metal angles require more powerful machines, such as hydraulic or electric models. The desired bending angle will determine the machine's capabilities. High-volume production requires automated machines for efficiency and consistency. Manual machines are generally more affordable, while automated machines can be more expensive.

Professionals have the training and experience to operate these machines safely, following all safety protocols and guidelines. Angle rolling machines require precise adjustments to achieve the desired bending results. Quality can be maintained only by professionals. Some angle rolling tasks may require specialized knowledge and techniques. It is better to leave the angle rolling to the pros. If you need one such service, you can contact a service company for your needs.