Safety Standards and Best Practices in Steel Fabrication

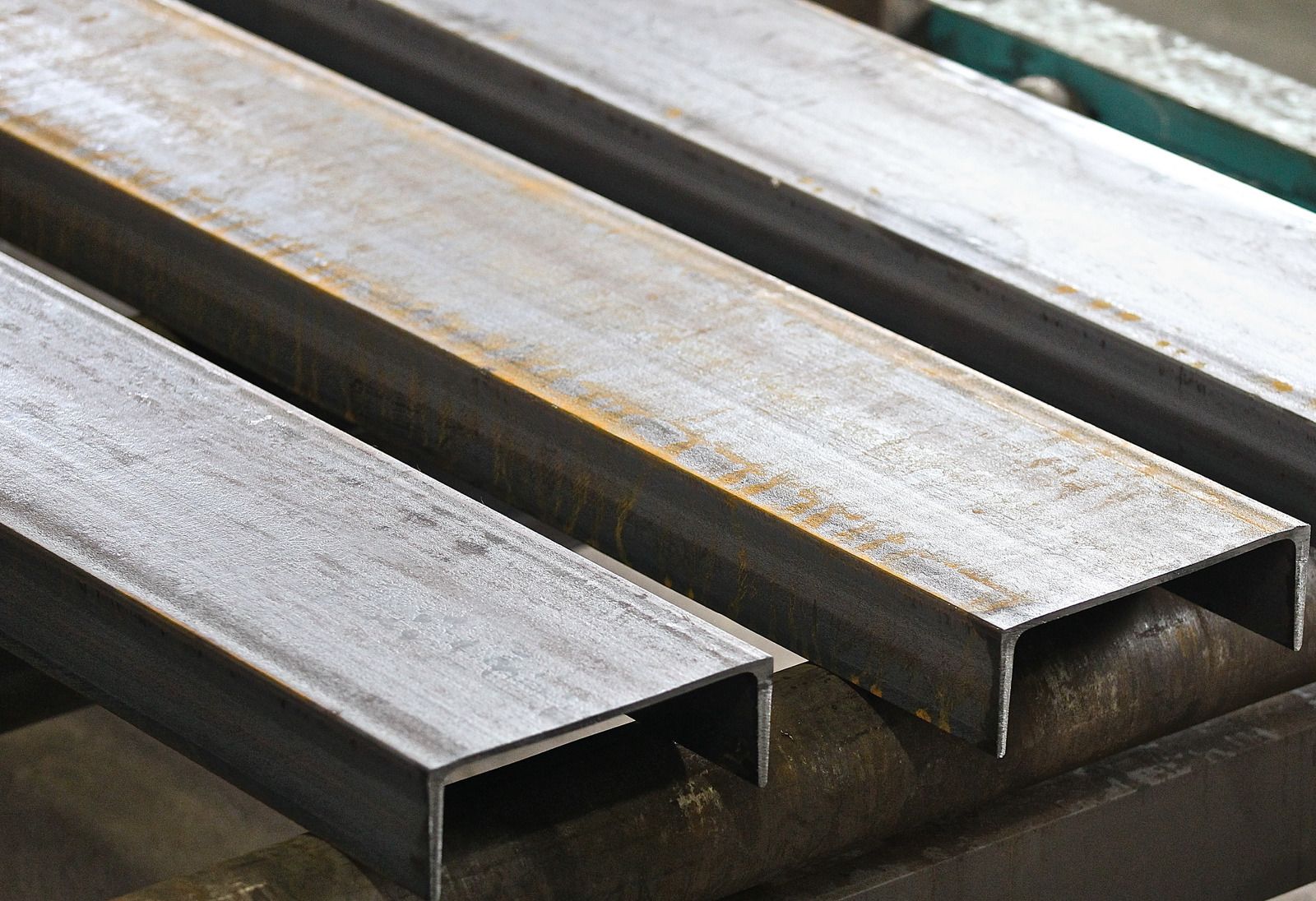

Steel fabrication is critical in various industries, including construction, automotive, and shipbuilding. Ensuring safety and adhering to best practices in this field is a regulatory requirement and a moral obligation to protect workers and ensure quality. This blog will explore the safety standards and best practices in steel fabrication.

Understanding the Risks

Steel fabrication involves cutting, bending, and assembling steel, which inherently comes with risks such as exposure to high temperatures, sharp objects, and heavy materials. Understanding these risks is the first step in mitigating them.

Safety Standards

1. Personal Protective Equipment (PPE)

Workers should always wear appropriate PPE, including helmets, gloves, eye protection, and steel-toed boots. This gear protects them from common hazards like sparks, debris, and falls.

2. Equipment Safety

All equipment should be regularly inspected and maintained. Machines with sharp edges or moving parts, like saws and drills, should have proper guards.

3. Ventilation and Air Quality

Fabrication often produces fumes and dust. Adequate ventilation systems are essential to maintain good air quality and protect workers' respiratory health.

4. Fire Safety

Given the use of welding and cutting torches, fire safety is paramount. Fire extinguishers should be readily available, and workers should be trained in fire prevention and response.

5. Noise Control

Fabrication shops can be noisy, potentially causing hearing damage. Noise control measures like sound barriers and earplugs or earmuffs are essential.

Best Practices

1. Training and Education

Workers should receive proper equipment use, safety protocols, and emergency response training. Regular safety drills and education sessions help reinforce this training.

2. Material Handling

Proper techniques for lifting and moving heavy materials are crucial. Using equipment like cranes and forklifts can minimize physical strain and prevent injuries.

3. Housekeeping

A clean and organized workspace is safer and more efficient. Regular housekeeping prevents accidents caused by slips, trips, and falls.

4. Stress Management

The high-paced environment in steel fabrication can lead to stress. Managing this through breaks, supportive management, and positive work culture is vital for safety.

5. Quality Control

Adherence to quality standards in fabrication ensures the integrity of the final product and prevents accidents that could arise from substandard materials or quality.

6. Compliance with Regulations

Staying updated with local and international safety regulations and ensuring compliance is crucial. It includes guidelines from organizations like OSHA (Occupational Safety and Health Administration).

7. Incident Reporting and Analysis

Reporting and analyzing every incident, even minor ones, helps understand potential risks and prevent future accidents.

The Role of Technology

Advancements in technology have a significant role in enhancing safety. Automation can reduce human exposure to hazardous tasks. Software for design and simulation can identify potential issues before fabrication begins.

Environmental Considerations

Environmental safety is also a part of best practices in steel fabrication. It includes proper disposal of waste materials and ensuring that the fabrication process minimizes its ecological footprint.

Parting Thoughts

Safety in

steel fabrication is an issue that requires a comprehensive approach, combining strict adherence to safety standards with a commitment to best practices. From personal protective equipment to advanced technology, every aspect plays a crucial role in safeguarding workers' well-being and ensuring the final product's quality. As the industry evolves, so must its approach to safety, ensuring that it remains a top priority in steel fabrication processes.