Everything You Need To Know About Plate Rolling

Have you ever wondered what plate rolling is all about? Though a bit technical, it is fascinating to know what this process entails. Plate rolling is a metal fabrication process that involves bending and shaping metal plates into cylindrical or conical shapes. It is widely utilized in various industries, including construction, manufacturing, and energy; interested already? Here will provide the following:

- A comprehensive overview of plate rolling.

- Covering its applications.

- The process involved.

- The benefits it offers.

1. The Process Of Plate Rolling:

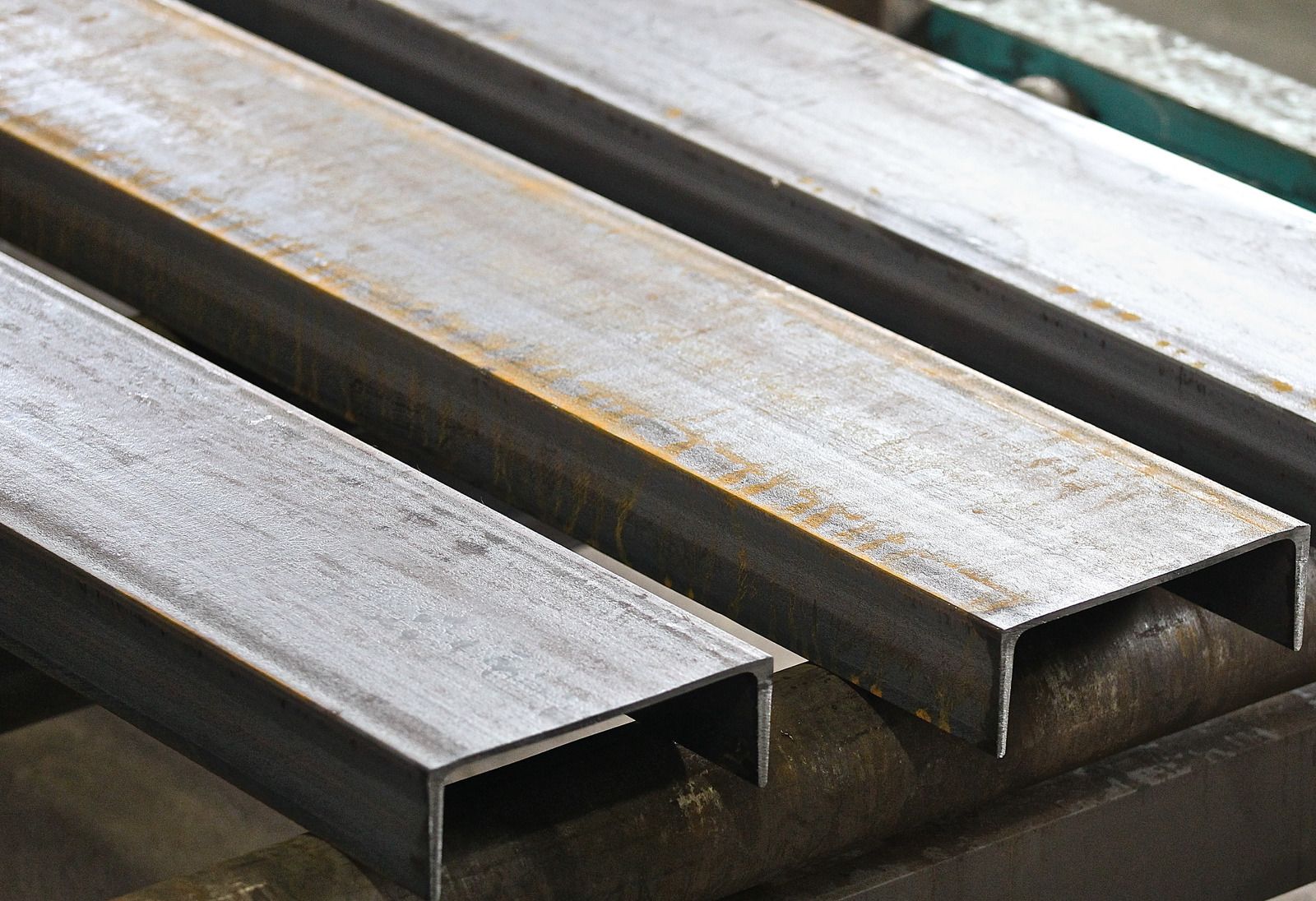

Plate rolling involves three primary steps: pre-bending, rolling, and post-bending. The plate edges are bent in the pre-bending stage to achieve a slight curvature. During the rolling phase, the plate is passed through a scale rolling machine, which applies force to shape the metal into the desired cylindrical or conical form. The post-bending step involves fine-tuning the curvature and meeting the desired specifications. Plate rolling machines come in various types, including pyramid-type, three-roll, and four-roll, each suited for specific applications.

2. What Are The Applications of Plate Rolling:

Plate rolling has extensive applications in many industries. It is commonly used to construct cylindrical structures like storage tanks, pressure vessels, and pipes. It is also employed in manufacturing large pipes for oil and gas transportation, as well as for fabricating structural components for bridges, offshore platforms, and industrial machinery. Plate rolling is favored for its ability to produce seamless and curved metal components, making it versatile for various applications.

3. Wholesome Benefits of Plate Rolling:

Plate rolling offers several advantages over other metal forming methods:

- It enables the production of large and complex metal shapes with high precision and accuracy. The ability to achieve a consistent curvature across the entire length of the plate ensures structural integrity and minimizes the need for other joining processes.

- Plate rolling allows for various materials to be used, including carbon steel, stainless steel, aluminum, and alloy metals. This versatility makes it suitable for diverse project requirements.

- Plate rolling provides cost-efficiency by reducing material waste and eliminating the need for complex fabrication techniques.

4. What About Quality Control and Accuracy:

Quality control is a critical aspect of plate rolling. Precise measurements and calculations are made to ensure the final product's desired curvature and dimensional accuracy. Skilled operators use specialized tools and equipment to monitor and adjust the rolling process, ensuring consistent results. Non-destructive testing methods such as ultrasonic or radiographic testing may also be performed to detect any potential defects or imperfections.

5. How Do You Know You Are Choosing a Plate Rolling Service Provider:

When considering plate rolling services, choosing a reputable and experienced service provider is essential. Look for an enterprise with a track record of delivering high-quality results, advanced machinery, and a skilled workforce. Ensure they can handle the size and thickness of your desired plates and the necessary certifications and expertise in the specific industry requirements. Collaborating with a reliable plate rolling service provider ensures your project is completed with precision, efficiency, and adherence to the highest quality standards.

Conclusion

In short,

plate rolling helps you get precision components. It is a versatile process, and the firms that go for it are sure to provide nothing but good quality. Understanding the plate rolling process, applications, and benefits will help you make proper decisions when choosing this technique for your metal fabrication needs. Look out for a reputed plate rolling service provider if that is what you want to opt for in your upcoming project.