Pipe & Tube Rolling Service

Significance of Pipe & Tube Rolling Contractor in Cincinnati, Ohio

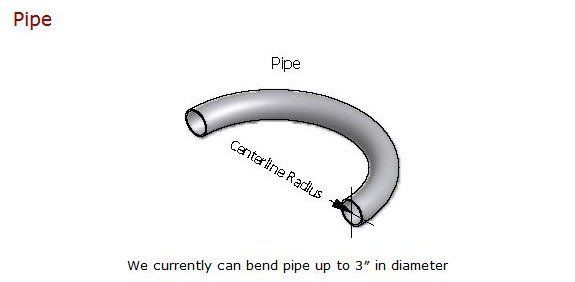

Rolled steel pipes and tubing for your next big construction job, we can provide it for you. We can bend pipes up to 5 inches in diameter, ensuring that even your larger-scale projects can be achieved.

Pipe & Tube Rolling Contractors in Cincinnati, Ohio, provide an invaluable service to the city and its surrounding areas. Rolling pipes requires specialized equipment that makes it possible to form complex shapes with high accuracy and repeatability. Pipe & Tube Rolling Contractors can create bends, arcs, flares, twists, annular rings, cones, or any other custom pipe shape desired by customers from materials like stainless steel tube or aluminum sheet metal, depending on the application. The skills required for this type of task are highly sought after due to their precision and reliability.

By utilizing advanced technology such as computer numerically controlled (CNC) machines and experienced operators who understand how these tools work together, they can produce quality products quickly and efficiently. This allows them to serve industries such as automotive manufacturing, where time is often critical in getting parts machined correctly before going into production.

What Are The Best Methods For Pipe & Tube Rolling?

Pipe and tube rolling is a process that creates curved sections of metal from straight sections. It involves heating, stretching, and forming the metal into rolled shapes. The best methods for pipe & tube rolling depend on the desired shape, size, and material being used. Generally speaking, cold or hot roll bending is a good option for pipes with small diameters, while rotary draw bending works well for larger-diameter pipes. Other techniques, such as swaging and extrusion, can also be employed depending on the application requirements. Additionally, various automated systems are available that can simplify the process by controlling variables like speed, pressure, and temperature to produce consistent results each time.

What Are the Different Uses of Pipe & Tube Rolling in Steel Fabrication?

Pipe and tube rolling in steel fabrication is an essential process to create curved pipe or tube sections. It involves passing the metal through a set of rollers that shape it into the desired form. This technique makes it possible to produce pipes and tubes with complex shapes, making them suitable for use in many applications, such as automotive piping systems, plumbing systems, structural supports, stair rails, and handrails. Pipe and tube rolling can also be used to create custom-shaped items like decorative rings, brackets, or frames. Additionally, this method is often employed when creating parts from thicker materials that other methods cannot easily bend. In short, pipe & tube rolling offers a range of versatile options for steel fabrication projects.

FAQ's

What is pipe and tube rolling, and how does it differ from bending?

Pipe and tube rolling involves gradually curving straight metal tubing into large, consistent radii or spirals using precision rolling machines. Unlike sharp-angle bending, which creates localized deformation, rolling forms smooth, continuous arcs with minimal distortion to wall thickness or shape. Harvey Brothers Inc. specializes in rolling services for structural, architectural, and industrial applications in Cincinnati. This method is ideal for large-radius curves, rings, and coil work, providing more uniformity and strength preservation than traditional bending techniques.

What materials can Harvey Brothers Inc. roll?

We work with a wide range of materials, including carbon steel, stainless steel, aluminum, copper, brass, and specialty alloys. Each material has unique rolling properties, with variables like wall thickness, diameter, and temper affecting formability. Our Cincinnati-based team assesses your project’s requirements and recommends appropriate materials or wall thickness adjustments for optimal rolling results. Whether your job calls for structural tubing, ornamental brass, or industrial-grade stainless steel, we have the equipment and expertise to roll it accurately and efficiently.

What industries typically use pipe and tube rolling services?

Rolled pipes and tubes serve countless industries, including construction, architecture, shipbuilding, infrastructure, public art, transportation, energy, and industrial manufacturing. In Cincinnati, Harvey Brothers Inc. frequently rolls steel for building canopies, handrails, architectural arches, industrial supports, storage racks, and conveyance systems. Custom rolling is also essential for processing plants, stadiums, theme parks, and public infrastructure projects where precision curves or circular components are necessary. We tailor our services to meet each industry’s specific tolerances and material standards.

What factors determine the minimum radius you can roll a pipe or tube?

Minimum rolling radius depends on material type, wall thickness, outer diameter, and cross-sectional shape. Thicker-walled pipes can typically be rolled to tighter radii without risk of flattening or wrinkling, while thinner materials require larger radii to maintain structural integrity. Harvey Brothers Inc. carefully reviews these factors, applying industry-standard formulas and in-house expertise to recommend safe, practical radii for each job. Providing your material specifications upfront allows us to optimize rolling outcomes and avoid costly deformations.

Is there a risk of distortion when rolling pipes and tubes?

Some degree of distortion — such as ovalizing, surface marks, or wall thinning — is possible during rolling, especially on thin-walled or large-diameter materials. However, professional operators using well-calibrated rolling machines can minimize these issues. Harvey Brothers Inc. uses precision tooling and multi-pass rolling techniques to control deformation, preserving dimensional accuracy and cosmetic quality. In cases where distortion tolerance is minimal (e.g., for architectural or visible applications), we work with clients to select optimal materials and rolling parameters.

Can Harvey Brothers Inc. roll non-round tubing like square or rectangular sections?

Yes — we offer rolling services for square, rectangular, and even custom-extruded tube profiles. These shapes require special attention, as their flat faces and corners behave differently during rolling compared to round pipes. Our Cincinnati team uses specialized dies, mandrels, and controlled rolling pressures to maintain cross-sectional integrity and minimize twisting or bowing. Rolled square or rectangular tubing is often used for signage frames, decorative arches, public structures, and modern architectural designs requiring crisp, consistent curves.

What’s the typical turnaround time for pipe and tube rolling services?

Lead times depend on material availability, job complexity, quantity, and current shop scheduling. Simple jobs with in-stock materials may turn around in 2–5 business days, while complex projects or large production runs could require 1–3 weeks. At Harvey Brothers Inc., we prioritize clear scheduling, offering upfront delivery estimates upon quote approval. Rush jobs can often be accommodated for Cincinnati clients with urgent deadlines, and we advise lead times honestly to avoid disruptions to your project schedule.

Can you roll customer-supplied materials, or must I purchase through you?

We can work with both customer-supplied and in-house sourced materials. If you already have specific pipe or tube stock for your job, simply provide it along with your project specs, and we’ll handle the rolling. Harvey Brothers Inc. also maintains relationships with trusted Cincinnati and national metal suppliers and can procure material on your behalf if desired. We verify that all materials meet rolling suitability before processing to ensure quality results and minimize material waste.

How do you ensure accuracy and consistency during rolling?

Precision rolling involves calibrating machines, measuring radii at multiple stages, and using multi-pass techniques for tight tolerances. Harvey Brothers Inc. uses pre-set rolling programs, custom dies, and in-process measurements to maintain uniformity throughout each batch. For projects requiring multiple matching pieces, we implement controlled setups and verification protocols to ensure consistent arcs and dimensions. If your project requires certified tolerances, we can provide dimensional inspection reports to document compliance for your records.

What are common misconceptions about pipe and tube rolling?

A frequent misconception is that all materials roll the same way or that tighter radii are always possible. In reality, material grade, temper, and wall thickness dramatically affect formability and minimum radii. Another myth is that rolling won’t cause surface marks or ovalizing — while skilled operators minimize these, some effect is normal and can be managed with proper finishing or thicker walls. Harvey Brothers Inc. educates Cincinnati clients on realistic outcomes, preventing unexpected results and costly rework.

Harvey Brothers Inc.

- The Best-in-Class Pipe & Tube Rolling Service Providers in Cincinnati, Ohio.

Harvey Brothers Inc.

is the leading provider of pipe and tube rolling services in Cincinnati, Ohio. With over 42 years of experience in providing top-notch quality fabrication services, we are committed to meeting the needs of our clients with superior craftsmanship and industry-leading technology. Our professional team is dedicated to delivering high-quality results reliably within your budget constraints and on-time delivery schedules every time! With a commitment to customer satisfaction and value-added services such as rapid prototyping capabilities that can reduce lead times by up to 80%, you know you can count on Harvey Brothers Inc., the best-in-class Pipe & Tube Rolling Service provider in Cincinnati, Ohio!